1965 Chevrolet C10 pickup of Dyson

Originally from Montreal, Dyson began working on cars when he was 14 years old. No one introduced him to the nuances of mechanics. Instead, he taught himself, reading maintenance manuals and studying exploded diagrams.

He became so proficient that, in his dad’s garage, he set up a neighbourhood service shop, doing oil changes, brakes and tune-ups. This gig saw him through university, and upon graduating he moved west to Calgary.

“All the while, I was doing my own tinkering on vehicles, servicing and maintaining our family cars,” Dyson says.

A couple of those vehicles were Corvettes – he owned a 1974 model, while his dad, who also came west, had a 1975 ’Vette. Dyson modified both for more power.

Then, he finally got the 1965 Chevrolet pickup. The truck was originally bought by the sheet metal company from Fowlie Motor Sales, a GM dealer at 1413 Centre St. North in Calgary. When Dyson bought it, he was only the truck’s second owner.

At the end of the Fifties, General Motors completely modernized its line of pickups and launched, in 1960, the C/K series of trucks, with C denoting two-wheel drive and K four-wheel drive platforms. Offered in step side or fleet side configurations with either a 6.5-foot or 8-foot box, this first generation of C/K models paved the way for a long history of GM haulers.

Andy Dyson of Calgary is the second owner of this 1965 Chevy pickup truck. He bought it 30 years ago, and has modified it with several upgrades while continuing to use it as a hauler.

Dyson’s most recent upgrade to the ’65 Chevy truck was to install a 350 cubic-inch GM crate engine — here’s the final result.

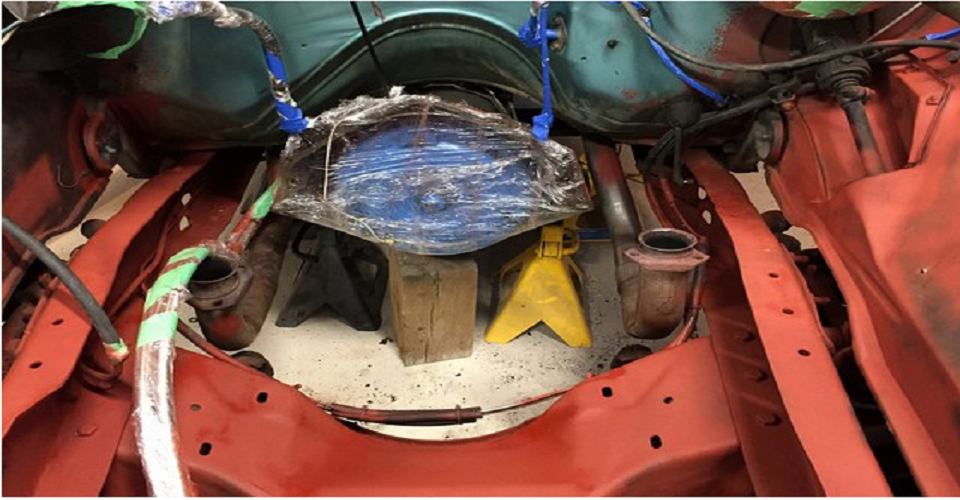

After using his 1965 Chevrolet C10 pickup truck with the original 283 cubic-inch engine for many years, owner Andy Dyson replaced the powerplant with a 350 cubic-inch GM crate engine. Here, he’s sorting out some of the plumbing and wiring.

As Dyson bought it, the two-wheel drive fleet side Chevy was equipped with a column-shift three-speed transmission and a 283 cubic-inch V8 engine.

“I did a bit of work to it right away,” Dyson says. “I changed the dual barrel carburetor to a four-barrel, upgraded the alternator, and repaired and replaced some of the wiring.”

Other modifications made over the years included adding a more modern HEI electronic ignition distributor and installing better wheels and tires. Power disc brakes replaced the manual drums and a dual exhaust went on. It was lowered 2.5-inches in the front and four inches in the rear.

Dyson cut out some rusty areas of metal, and with his MIG-welding equipment, added new metal patches. Meanwhile, rusty front fenders were replaced with new pieces.

“One day, the three-on-the-tree shifter jammed on me, so I replaced that with a floor shifter connect

Most recently, Dyson and Mike Melanson, a friend from the Foothills Street Rod Club, pulled out the original 283 cubic-inch engine. With the original engine out of the way, Dyson’s wife Shelley volunteered to help clean up the engine bay using steel wool and sandpaper. Next, Dyson primed and painted the front frame rails and inner panels before Melanson came back to help install a 350 cubic-inch GM crate engine.

It is quite quick and a lot of fun.

The engine swap allowed Dyson to add power steering, and he installed a new radiator and electric cooling fan at the same time.

His next project is replacing the tailgate. The original has some rust holes, and Dyson picked up a GM restoration unit from Golden Leaf Automotive Muscle Car Parts & Molding in Woodbridge, Ontario. After that, he wants to replace the wood in the floor of the truck box and re-do the interior.